Uganda’s Large Chicken Farm Embraces Automation with State-of-the-Art Sorting Equipment

Time : 2025-04-27

In the heart of Uganda, a large chicken farm has revolutionized its operations by introducing some of the most advanced automatic sorting equipment. This move not only showcases the country’s commitment to agricultural innovation but also highlights the potential of technology in boosting productivity and efficiency in the poultry industry. Let’s dive into how this farm is leveraging these cutting-edge tools to take its business to new heights.

The Challenge of Manual Sorting

For years, chicken farmers like those in Uganda have relied on manual sorting to categorize their birds. This process is not only time-consuming but also prone to human error. Sorting chickens by weight, age, and quality is a meticulous task that requires a significant amount of labor and expertise. Moreover, it’s a task that can be physically demanding for the workers involved.

The Introduction of Automatic Sorting Equipment

Recognizing the need for a more efficient solution, the large chicken farm in Uganda decided to invest in automatic sorting equipment. This move was not just about reducing labor costs or improving worker conditions; it was about embracing the future of agriculture.

The farm management conducted thorough research to find the best solution for their needs. They were looking for a system that could handle a high volume of birds, be reliable, and offer accurate sorting. After careful consideration, they settled on a state-of-the-art automatic sorting machine that would change the game for them.

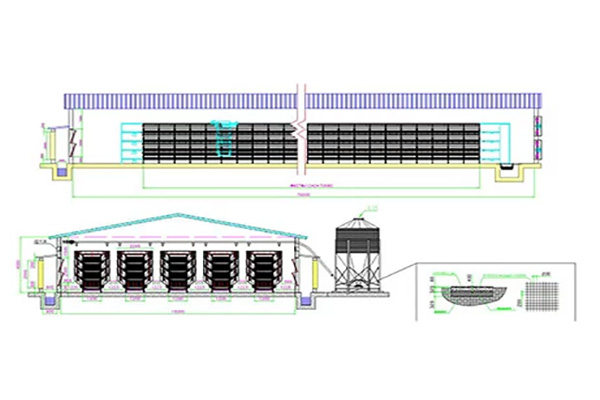

How the Automatic Sorting Equipment Works

The equipment is designed to efficiently sort chickens based on various criteria. Here’s a breakdown of how it works:

1. Weighing: The chickens are first weighed using a precision scale. This data is crucial for determining the birds’ age and overall health.

2. Age Estimation: Using sophisticated algorithms, the system estimates the age of the chickens based on their weight. This information is vital for ensuring that the birds are processed at the right time.

3. Quality Assessment: The equipment is equipped with high-definition cameras that capture images of the chickens. These images are analyzed to determine the quality of the birds, including any potential defects.

4. Sorting: Based on the collected data, the system automatically segregates the chickens into different categories. These categories can be tailored to meet the farm’s specific requirements, such as age, weight, and quality.

Benefits of Automatic Sorting Equipment

The introduction of this automatic sorting equipment has brought numerous benefits to the large chicken farm in Uganda:

1. Increased Productivity: The automation of the sorting process has significantly increased productivity. The farm can now sort a larger number of chickens in a shorter amount of time, allowing for more efficient operations.

2. Reduced Labor Costs: By automating the sorting process, the farm has been able to reduce its reliance on manual labor. This not only saves on labor costs but also improves the working conditions for the farm’s employees.

3. Improved Accuracy: The precision of the automatic sorting equipment ensures that the chickens are sorted correctly, reducing the likelihood of errors and minimizing waste.

4. Enhanced Data Analysis: The data collected during the sorting process can be used to make informed decisions about the farm’s operations. This includes optimizing feed formulations, improving health protocols, and making strategic business decisions.

The Future of Poultry Farming in Uganda

The adoption of automatic sorting equipment at the large chicken farm in Uganda is a testament to the potential of technology in transforming the poultry industry. As more farms in the country embrace similar innovations, we can expect to see a significant shift in the way poultry is produced and managed.

Conclusion

In conclusion, the large chicken farm in Uganda has made a bold move by investing in automatic sorting equipment. This decision not only demonstrates the farm’s commitment to innovation but also sets a precedent for other poultry farms in the region. As technology continues to evolve, it’s likely that we’ll see more farms following in the footsteps of this forward-thinking operation. The future of poultry farming in Uganda is bright, and it’s all thanks to the power of automation and technology.