Automatic Lighting Equipment for 10,000 Chicken Farms in Uganda: Revolutionizing Farm Efficiency

Time : 2025-04-23

In the bustling heart of Uganda, where agriculture is the backbone of the economy, the chicken farming industry is booming. With thousands of farms scattered across the country, each aiming to maximize production and minimize costs, there’s a growing demand for efficient and reliable lighting solutions. That’s where automatic lighting equipment for 10,000 chicken farms in Uganda comes into play. Let’s dive into how this technology is transforming the industry and what it means for the future of chicken farming in Uganda.

Understanding the Lighting Needs of Chicken Farms

Chickens are creatures of habit, and consistent lighting is crucial for their health, growth, and overall well-being. Traditionally, farmers relied on manual switches and timers to manage lighting in their chicken coops. However, this method is not only time-consuming but also prone to human error. With automatic lighting equipment, farmers can now enjoy precise control over the light cycles, ensuring that their chickens are well-lit, whether it’s day or night.

Benefits of Automatic Lighting Equipment

1. Improved Growth Rates: By mimicking natural light patterns, automatic lighting equipment can boost the growth rates of chickens. Consistent lighting encourages them to eat, sleep, and grow more efficiently, leading to a healthier flock and increased productivity.

2. Energy Efficiency: Traditional lighting systems are often inefficient, wasting energy and increasing operational costs. Automatic lighting equipment is designed to be energy-efficient, reducing electricity bills and contributing to a more sustainable farming practice.

3. Enhanced Egg Production: Proper lighting is key to maximizing egg production. Automatic lighting equipment ensures that chickens are exposed to the right amount of light throughout the day, leading to higher egg yields.

4. Healthier Chickens: Consistent lighting patterns can help reduce stress and aggression among chickens, leading to a healthier flock and fewer health issues. This, in turn, reduces veterinary costs and ensures better quality meat and eggs.

Implementing Automatic Lighting in 10,000 Chicken Farms

Introducing automatic lighting to 10,000 chicken farms in Uganda is no small task. It requires careful planning, quality equipment, and skilled installation. Here are some key steps involved in the process:

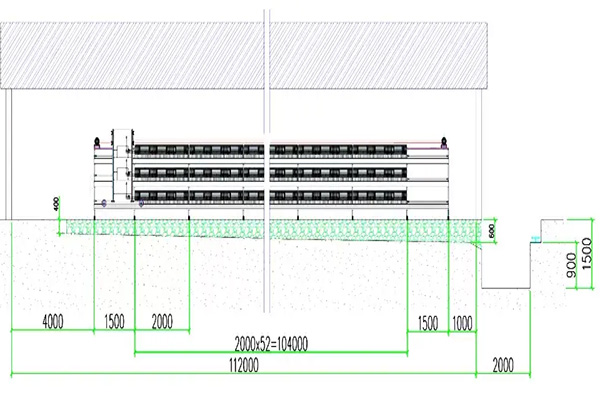

1. Assessment: Before installing automatic lighting equipment, it’s essential to assess the specific needs of each farm. This includes the size of the farm, the number of chickens, and the existing lighting infrastructure.

2. Choosing the Right Equipment: Selecting the right lighting equipment is crucial. Look for systems that offer adjustable light intensity and duration, as well as features like remote monitoring and control.

3. Professional Installation: Install the lighting equipment according to the manufacturer’s guidelines. It’s recommended to hire professionals to ensure that everything is set up correctly and safely.

4. Training: Train farm workers on how to operate and maintain the automatic lighting systems. This includes troubleshooting common issues and ensuring that the equipment runs smoothly.

Case Studies: Success Stories from Uganda

Several chicken farms in Uganda have already embraced automatic lighting equipment, and the results have been nothing short of impressive. Here are a couple of success stories:

Case Study 1: Nakasero Chicken Farm

Nakasero Chicken Farm, located in the capital city of Kampala, was facing challenges with inconsistent lighting and high energy bills. After installing an automatic lighting system, the farm experienced a 20% increase in growth rates and a 15% reduction in energy costs. The owner, Mr. Kato, was thrilled with the results and plans to expand the system to other areas of the farm.

increase in growth rates and a 15% reduction in energy costs. The owner, Mr. Kato, was thrilled with the results and plans to expand the system to other areas of the farm.

Case Study 2: Kikuletwa Chicken Cooperative

The Kikuletwa Chicken Cooperative, a collective of small-scale farmers, was struggling with low egg production. By implementing an automatic lighting system, the cooperative saw a 30% increase in egg yields. This not only improved the income of the farmers but also provided a more consistent supply of eggs to local markets.

The Future of Chicken Farming in Uganda

As technology continues to advance, the future of chicken farming in Uganda looks promising. Automatic lighting equipment is just the beginning. We can expect to see further innovations in the agriculture sector, including better feed systems, more efficient water management, and advanced monitoring technologies.

By embracing these advancements, farmers in Uganda can ensure a sustainable and prosperous future for their industry. With the right tools and technologies, the potential for growth and success is immense.

Conclusion

Automatic lighting equipment for 10,000 chicken farms in Uganda is more than just a technological upgrade; it’s a game-changer for the entire industry. By improving growth rates, reducing costs, and enhancing overall farm efficiency, these systems are set to revolutionize the way chickens are raised in Uganda. As farmers continue to invest in these technologies, the future of chicken farming in the country is looking brighter than ever.